Posted by Armin on Tuesday, January 04, 2011

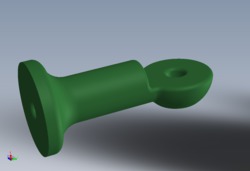

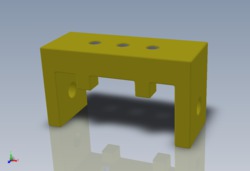

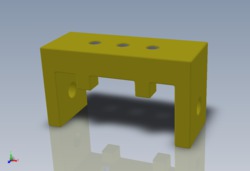

.jpg) Concept rendering: ballhead end attachment

Concept rendering: ballhead end attachment

.jpg) Printed "MothBones": ballhead end carries a small high-power IR LED array

Printed "MothBones": ballhead end carries a small high-power IR LED array

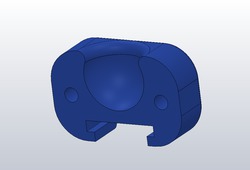

.jpg) Concept rendering cartoon: flat end attachment

Concept rendering cartoon: flat end attachment

A modular system of interlocking pieces for holding small gadgets in place. Printed on the Daniel Lab's uPrint 3D Printer to fit a multitude of holding tasks. Standard 1/4-20 screws can be used to fasten together individual pieces. (Fall 2009 - 2010)

It's pretty common that I have to position small items such as light sources or electronics somewhere in my setup when conducting experiments. A lot of times, duct tape is the perfect quick fix. It's really hard to adjust the angle of a light source that's taped to a rod, though. And so I thought it would be nice to have a flexible, modular system with many degrees of freedom for holding small parts in place. My experimental rig uses 80/20 aluminum extrusions for framing, and therefore I wanted a system that can easily be attached to the frame as well.

Initially I designed such a modular holding system in Google Sketchup, with the idea that the finished pieces can be printed on the lab's 3D printer (Dimension uPrint). I've since redesigned them in Solidworks, which makes creating STL files for 3D printing much easier and more precise. Since I work on moths, and the parts looked like bones, I called them "MothBones".

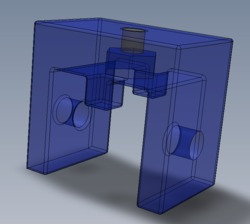

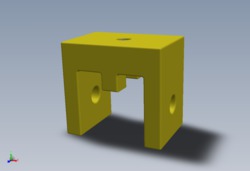

As the renderings on the right show, the pieces can be attached to each other in a variety of ways. Hex-nuts are press-fit into a slot at one end of each piece. This creates a strong thread for a 1/4-20 wing-screw that attaches the complementary piece to it. The second concept rendering shows these screws, as well as the attachment to the 80/20 aluminum base, and the ballhead unit.

Components

Straight connectors

| ID# | Component | Notes | Solidworks file |

|---|---|---|---|

| 1A |  |

ID: mothBones_holder_component1A. Single-head (end piece) | Solidworks |

| 2A |  |

ID: mothBones_holder_component2A. Dual-head for rotation in the same plane | Solidworks |

| 2B |  |

ID: mothBones_holder_component2B. Dual-head for 90 degree out-of-plane rotation | Solidworks |

Ball-head components

| ID# | Component | Notes | Solidworks file |

|---|---|---|---|

| BH-part-A |  |

ID: mothBones_ballHead_topA. Part A of the ballhead bracket. | Solidworks |

| BH-part-B |  |

ID: mothBones_ballHead_topB. Part B of the ballhead bracket. | Solidworks |

| BH-base |  |

ID: mothBones_ballHead_base. Ballhead that connects to rest of system. | Solidworks |

80/20 attachment components

| ID# | Component | Notes | Solidworks file |

|---|---|---|---|

| 3A |  |

ID: mothBones_holder_component3A. Connector between 80/20 sliders and straight components. | Solidworks |

| 4A_nut |  |

ID: mothBones_holder_component4A_nutInset. 1/4-20 nut can be pressed into a recessed hexagonal slot and functions as a thread for components attached from above. | Solidworks |

| 4A |  |

ID: mothBones_holder_component4A. Attachment for 10-wide 80/20 profile. Same as 4A_nut, except without the recess for press-fitting a nut. The centered top hole can be threaded or used with self-tapping sheet metal screws instead. | Solidworks |

| 4B_nut |  |

ID: mothBones_holder_component4B_nutInset. 1/4-20 nut can be pressed into a recessed hexagonal slot and functions as a thread for components attached from above. | Solidworks |

| 4B |  |

ID: mothBones_holder_component4B. Attachment for 20-wide 80/20 profile. Same as 4B_nut, except without the recess for press-fitting a nut. The centered top hole can be threaded (1/4-20) instead. | Solidworks |

STL files

Please download the zipped STL files for all components from the "file attachment" link near the bottom of the page.